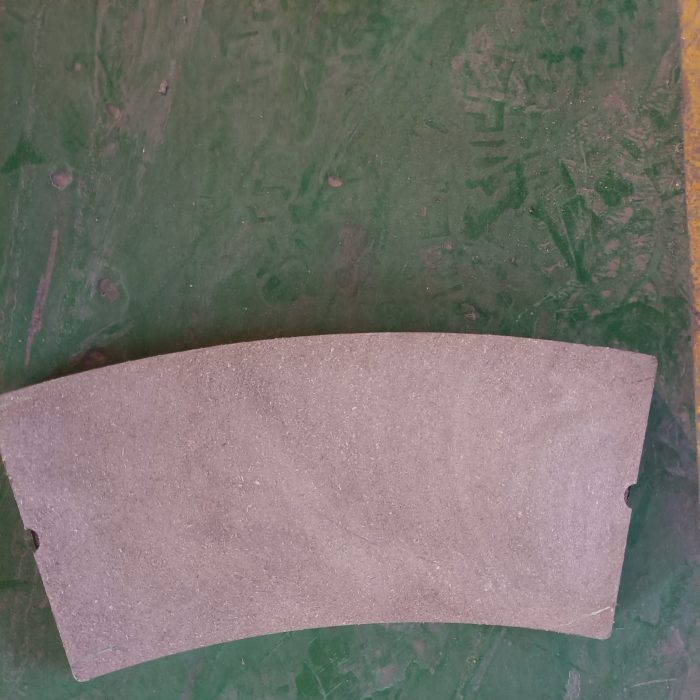

1. Structure and Composition

Brake pads for oil drilling rigs are significantly larger than automotive brake pads and require extreme heat resistance:

-

Backing Plate: LONGWELL utilizes high-quality carbon steel or alloy steel to ensure zero deformation under high-pressure conditions.

-

Friction Material Layer:

-

Non-Asbestos Material: In compliance with modern industrial standards, LONGWELL pads are 100% non-asbestos, formulated from a high-performance composite of resin, semi-metallic fibers, ceramic fibers, and lubricating fillers.

-

High Friction Coefficient: Maintains a stable friction coefficient—typically between 0.40 and 0.50—even under high-temperature operation.

-

-

Accessories: Includes integrated wear indicators (sensors), anti-noise shims, and other essential hardware.

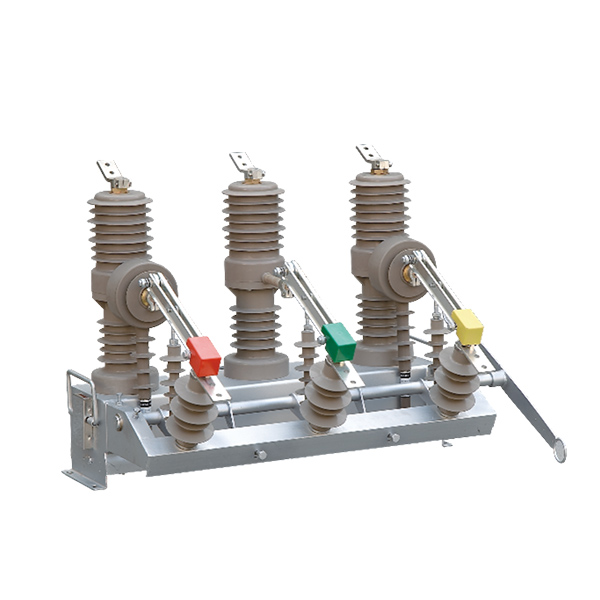

Drawworks Hydraulic Disc Brake Pads

2. Core Technology: Heat Dissipation and Wear Resistance

Given that oil drilling depths can reach several thousand meters, the heat generated during braking is immense:

-

Thermal Fade Control: LONGWELL brake pads are engineered to withstand instantaneous high temperatures ranging from 300℃ to 500℃ without compromising braking performance.

-

Cooling Compatibility: To manage these extreme loads, the drawworks brake discs are typically equipped with circulating water-cooling or forced air-cooling systems.

Drawworks Hydraulic Disc Brake Pads