Are you searching for a long-lasting critical component for your mud pump? This article delves deep into the core part—the crosshead—to answer all your questions and introduce how LONGWELL provides a solution.

Oil drilling mud pump crosshead AH36001-04.01A

Q1: What is a Crosshead in an Oil Rig Mud Pump? What is its Role?

A1: The crosshead is a core transmission component inside the power end of a mud pump, playing the critical role of "Motion Conversion and Precision Guidance." It connects to the connecting rod via a crosshead pin on one end and to the piston rod on the other. Its primary function is to convert the rotary motion of the crankshaft into the linear reciprocating motion of the piston, while withstanding enormous lateral forces to ensure the piston runs smoothly and linearly within the fluid cylinder.

In essence, without a properly functioning crosshead, the entire power transmission of the mud pump fails. Therefore, choosing a high-quality crosshead is paramount.

Recommended Reading: Need More oil drilling mud pump power end spare parts

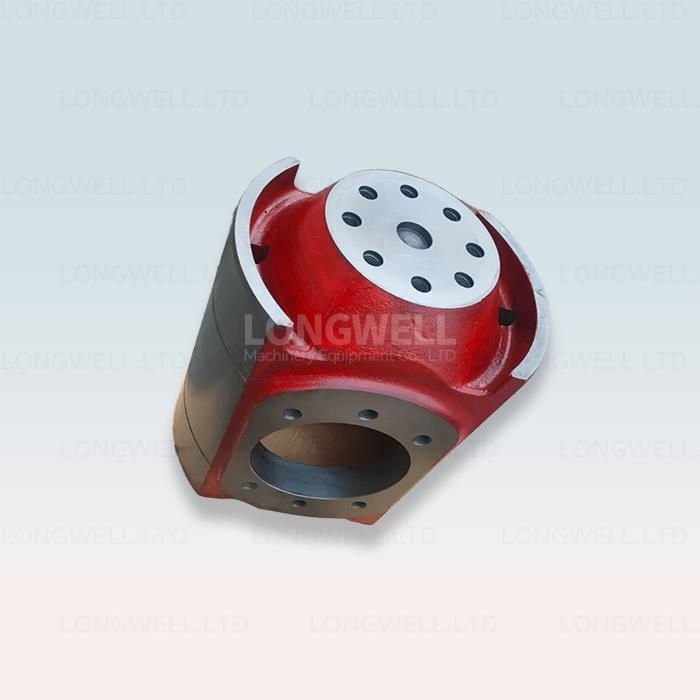

RSF Mud Pump Crosshead

Q2: What Severe Challenges Does the Crosshead Face? Why is it Prone to Damage?

A2: The crosshead operates in what can be called "hellish conditions." Its damage is typically caused by a combination of extreme factors:

- Extremely High Alternating Loads: Withstands huge reciprocating impact forces from high drilling fluid pressure.

- Severe Friction and Wear: High-speed reciprocating sliding within the crosshead shoes demands excellent wear resistance.

- Risk of Lubrication Failure: Under heavy load and high temperature, the lubricating oil film can easily break down, leading to dry or boundary friction.

- Potential Contamination: Even the finest impurities entering the friction pair can become "abrasives," accelerating wear.

Understanding these challenges makes it clear why standard parts cannot meet the demand. This is precisely where LONGWELL comes in—we design and manufacture crossheads specifically to withstand these extreme operating conditions.

Recommended Reading: More spare parts for oil drilling mud pump

Q3: What are the Unique Advantages of LONGWELL Crossheads in Terms of Material and Manufacturing Process?

A3: At LONGWELL, we believe that "material determines lifespan, and process determines precision." Our crossheads are not ordinary castings but are engineered masterpieces created through a series of precision processes.

| Feature | Ordinary Product | LONGWELL Solution | Value to Customer |

|---|---|---|---|

| Core Material | Ordinary carbon or low-quality alloy steel | Forged from high-quality alloy steel (e.g., QT600-3) | High core strength and toughness, resistant to fatigue and impact |

| Surface Treatment | Standard quenching, shallow hard layer | Deep nitriding or high-frequency quenching process | Surface hardness up to HRC 60+, wear resistance improved by 300% |

| Machining Precision | Traditional machining, average tolerance | Precision machining with 5-Axis CNC Centers | Perfect geometric tolerances ensure smooth installation, reducing misalignment and vibration |

| Lubrication Design | Traditional oil hole design | Optimized internal oil passages and oil reservoir structure | Forms an optimal lubricating oil film, reducing wear and thermal faults at the source |

We understand that a reliable crosshead can save you significant downtime and maintenance costs. Choosing LONGWELL means choosing peace of mind and efficiency.

Recommended Reading: Need more fluid end spare parts for oil drilling mud pump?

Q4: How to Identify When a Crosshead Needs Replacement? What are the Common Failure Modes?

A4: Identifying crosshead issues early can prevent more significant secondary damage. Watch for these warning signs:

- Abnormal Sounds: Clear, loud "clicking" or heavy pounding sounds from the power end.

- Abnormal Oil Pressure: Drop in lubricating oil pressure or abnormal rise in oil temperature.

- Performance Drop: Unstable pump pressure, insufficient discharge.

- Visible Damage: (During overhaul) Severe scoring, spalling, or cracks on the sliding surface.

Common failure modes include excessive wear, surface scoring, fatigue cracks, and crosshead pin bore expansion. To prevent these, insisting on using genuine LONGWELL parts and following standardized maintenance procedures is the best preventative measure.

Recommended Reading: Check BOMCO mud pump power end parts

Q5: As a Procurement Manager, Why Should I Choose LONGWELL Crossheads?

A5: Choosing LONGWELL means you get not just a part, but a complete Worry-Free Drilling Operation Solution.

- Excellent reliability: Our crossheads are designed for a service life that far exceeds industry standards, significantly extending your mud pump’s overhaul cycles and maximizing your return on investment.

- Global Supply Chain Support: No matter where your rig is in the world, we can provide responsive logistics and localized inventory support to ensure your operations are never interrupted.

- Professional Technical Service: Our team of engineers provides comprehensive technical support, including installation guidance and fault diagnosis. We are your technical partner, not just a supplier.

- Excellent Cost-Performance: While the initial investment might be slightly higher, the longer service life and significantly reduced downtime will result in a lower Total Cost of Ownership.

Contact the LONGWELL sales team now to get a customized quote and technical data sheet for your specific equipment model! Let us, the professionals, become the most reliable link in your supply chain.

We hope this article provides a comprehensive understanding of the mud pump crosshead. If you have any questions or specific needs, please do not hesitate to contact us